DRY AND WET RISER SERVICING AND MAINTENANCE

DRY AND WET RISER SERVICING AND MAINTENANCE

A visual inspection every 6 months and a wet test annually are required. All buildings which have fire risers must comply with the standard BS9990/2006. Failure to do so may invalidate your insurance.

Annual Pressure Testing

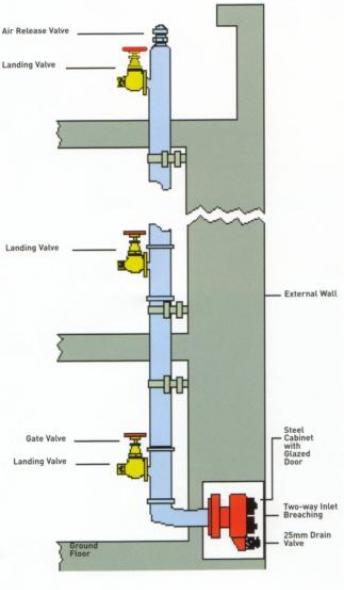

For dry risers this normally entails connecting the inlet to a Fire Pump and water supply, normally twin lines of 70 mm fire hose from a Towns mains Hydrant to the Fire Pump then twin lines of 70mm fire hose to the Dry Riser inlet.

The system is then completely charged with water to a pressure of 10 Bar measured at the inlet for a period of at least 15 minutes. During this period an inspection is made to ensure there is no leakage of water at any of the joints or landing valves/water outlets. Once the pressure test is completed the system must be drained so it is left ready for immediate use in the event of a fire breaking out.

In the event of a system failure due to inability to hold pressure for the recommended 15 minutes at 10 bar (at the inlet), a retest will be required.

For Wet Risers there are additional checks, on cleanliness of storage tanks, booster pumps and associated mechanical and electrical equipment.

6 month visual inspection

Checking

All outlet valves open and close; leave closed checking strap and lock if applied.

All outlet washers

Check for missing blank cap and chains, replace as required.

Check that all hand wheels and nuts are undamaged and in place

Check Landing outlets are in place and undamaged

Check the inlet cabinet, door glass and lock for damage and corrosion.

Check drain valve and inlet breeching valve springs are free moving and in good condition.

Check all required signage are present and correct.

Maintenance and remedial repairs (as required)

Replacing outlet washers

Repair or replace valves (replacing strap and lock where required)

Replace blank caps and chains.

Repair or replace hand wheels and nuts.

Repair and replace landing outlets.

Replace the inlet cabinet and door glass.

Repair the inlet breeching valve springs and replace rubbers.

Supply dry/wet riser signage to all floors where necessary.

Should the systems pipe work be altered (e.g. building alterations, extensions etc, then a full re-commissioning flow test will be required.

If you need us now please call

our 24-hour hotline on

0800 999 4343